By ECHO Volunteer Bob Phelps

Poly-Propagators Build Materials:

• 4 2x4 pressure treated lumber

• 3” Deck Screws

• Square

• Plexiglass

• Rolling wheels (if desired)

• Stainless Screws

• Wood drill bits (must have point on bit) - see photo

Building Process:

-

Cut 2 2x4’s 25 1/2”for base

-

Cut 2 2x4’s 28 1/2” for base

-

Screw together using 8 screws - see pictures

-

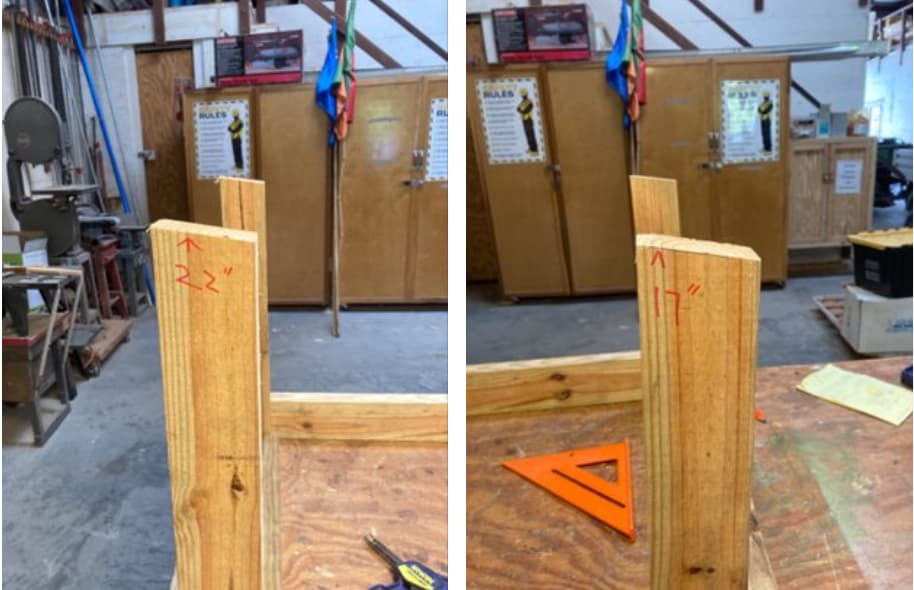

Cut 2 2x4’s 22” for uprights

-

Cut 2 2x4’s 17” for uprights

-

Attach as shown on picture. Make sure they are straight using a square tool. Both ways, temporarily attach with clamps - see picture. You choose height and angle desired.

-

Mark upright wood & cut angles — test fit. If OK screw uprights using 8 screws

-

Measure top boards ( approximately 30”). Make sure they are long enough on the bottom of board.

-

Mark angle on both & cut (approximately 25 1/4”) - test fit. If correct, use 8 screws to attach front & back top boards. (be careful of the upright screws already in place).

-

Install plastic using thin wood and staples and wire mesh - see picture. The plastic is what creates the water reservoir for the plants and maintains humidity levels. The wire mesh under the plastic is to give structure and support to the plastic and hold the seeding trays. The mesh is optional if the end product is sitting on top of a table or otherwise supported. An additional option would be to install wheels/castors if desired.

-

We cut cardboard to make a pattern for the plexiglass - see picture

-

To cut plexiglass use a skill saw, but turn the blade around backwards. Go slow, it will be messy. Use a flat file to clean up edges.

-

Test fit the plexiglass; if it is too large, use a sander to adjust the fit. If the plexiglass is too small add a piece of lumber.

-

Use your special wood drill bit (see photo) to cut holes in the plexiglass. Do no drill fast, let the bit do the work.

-

Install the plexiglass and attach with stainless steel screws. I use only 4 per opening.

-

To hold the top piece of plexiglass I added 2 small boards on the top & bottom.(see picture)

The final product including sliding side door to allow easy access when polypropagator is on the table.