ECHO Asia has tested three small scale biochar kilns to determine how the kiln design influences biochar characteristics. This post introduces some of our preliminary data, and we’d love to hear how these data match your own experiences. We plan to share more in an upcoming ECHO Development Note.

A note of thanks to the National Metal and Materials Technology Centre of Thailand, who we collaborated with on this trial and who conducted the analysis.

Background

The study on biochar production was conducted using three types of kilns: the Retort Biochar Wood Vinegar Kiln (Retort Kiln), the Top-Lit Updraft Biochar Stove (TLUD), and the Kon-Tiki Biochar Stove (Kon-Tiki). Tests were conducted at ECHO Asia Impact Centre in Chiang Mai in April 2025. Maize cobs were used as the biomass in all three kilns.

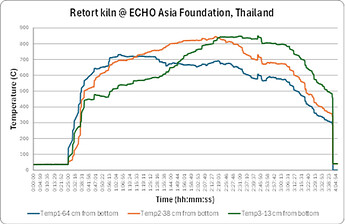

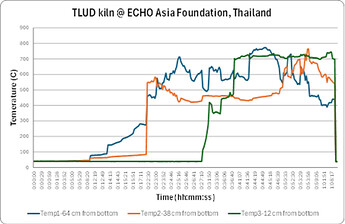

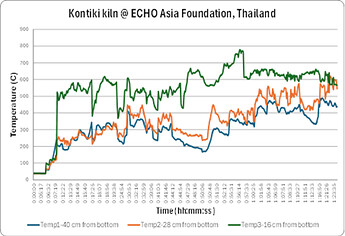

Temperature measurements were taken at three levels (top, middle, and bottom) for each kiln. See images below of the kilns, and graphs of pyrolysis temperature and duration.

Retort Kiln

TLUD Kiln

Kontiki Kiln

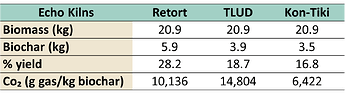

Yield and CO₂ Emissions:

The results of biomass pyrolysis is the three kiln designs were analyzed to estimate the ratio of biochar yield to biomass input. The findings showed that the Retort kiln produced the highest yield, with 28.2% of the maize cob biomass converted into biochar, followed by the TLUD kiln at 18.7%, and the Kon-Tiki kiln with the lowest yield at 16.9%.The retort kiln results in the highest pyrolysis temperature and longer duration, followed by the TLUD. These kilns are likely to produce high quality biochar with higher porosity and lower tar residue. The resulting produce is likely to be suitable for use in water filtration. The Kon-tiki is also capable of producing reasonable quality biochar for use as a soil amendment, but this will be more variable. The retort kiln is higher yielding than the other kilns and also produces wood vinegar as a by-product.

Carbon dioxide (CO₂) emissions, were measured as grams of gas per kg of biochar produced. The highest emissions were observed from the TLUD Kiln, with a value of 14,804 g CO2/kg biochar, followed by the Retort Kiln at 10,136 g/kg, while the Kon-Tiki Kiln exhibited the lowest emission at 6,422 g/kg. This is a surprising result, and further testing is required to confirm. The reason why the retort kiln has higher emissions than the Kon-tiki may be due to the use of a fire external to the kiln to generate heat.

Biochar Properties:

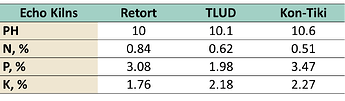

Physical properties of the biochar resulting from each kiln was analyzed. A small subset of these data is presented below.

pH values of above 10 are in the range of soils tests that ECHO has previously conducted. There does not appear to be a trend in one kiln design resulting in higher nutrient levels across all three elements.

What is your experience?

This research blog shares data from a single test performed on each kiln. The data match current understanding about kiln physical performance, yield, and the typical pH range of biochar. We caution against putting too much weight on emissions and nutrient content data until it is corroborated by further testing and field experience.

Whats your experience? Does it match this data?